Expert manufacturer

KING TONY®’s know-how is at the heart of the success of powerful and sustainable tools. Each step of manufacturing a KING TONY® product is thought out, studied and validated in order to obtain a top-of-the-range tool, the quality always exceeding the international standards.

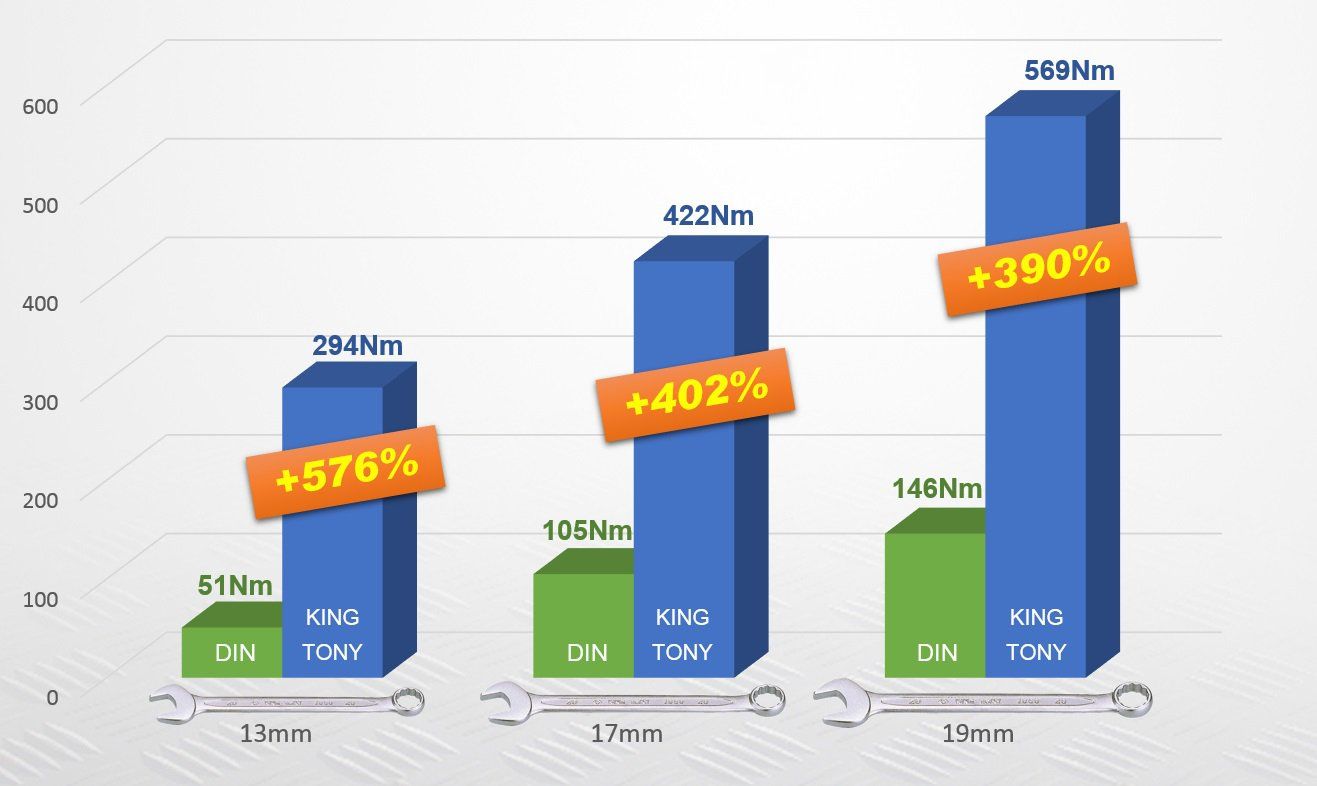

The required quality

Only the best tools come out of our factories. Indeed, KING TONY® imposes its own standard: at least 30% above

the DIN standard for hand tools, and 50% minimum

for impact tools.

Precision forging technology

Traditionally, during the forging process, the metal moves while still in the solid state. KING TONY® has specialized in forging technology to create a better metal configuration. Non-straight grain flow and softened corners extend the life of the socket, ensuring a strong and secure torque.

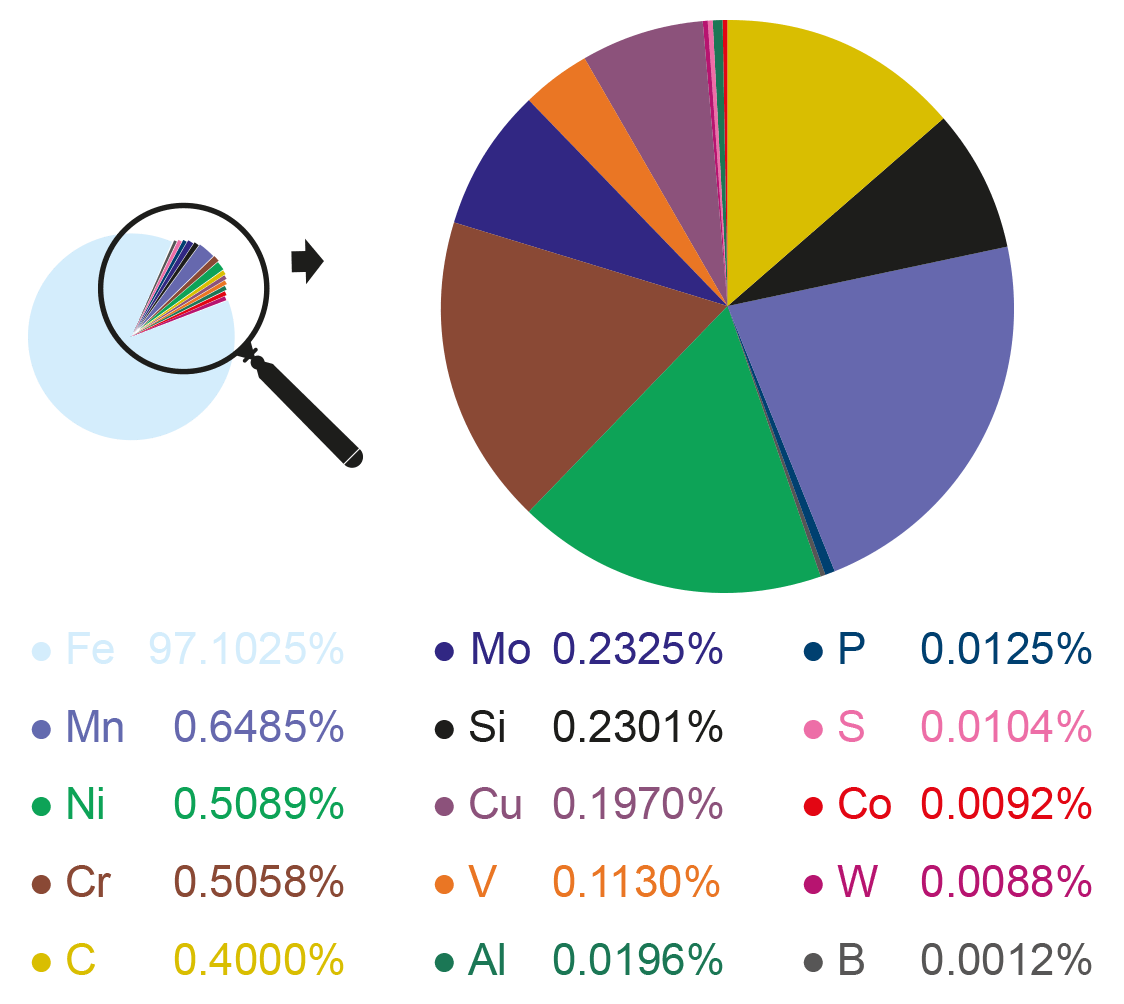

Mastery of heat treatment

Heat treatment involves changes of temperature over time. KING TONY® masters the heat treatment system, which ensures a good hardness of the metal, avoiding fragility. In the microstructural photo you can see that the elements are well distributed. Too much Troostite (Zn, Mn) will bring a low break point. A well distributed element (Fe) will lead to better resistance.

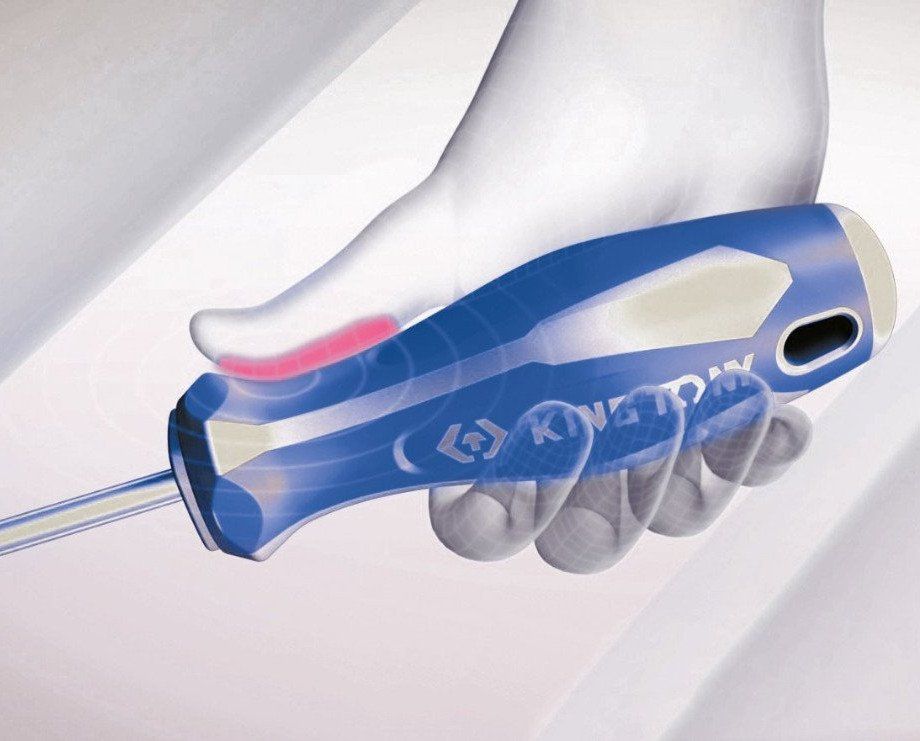

Health and safety

The continuous movement in professional work always brings fatigue and muscular tension. This results in increasing discomfort or even injury risks to users. The health and safety of its users is a major concern for KING TONY®. We strive to design a more comfortable and safe handling

of our products. For example, for our bi-material handles, we have selected TRB, a high performance thermoplastic rubber, obtained by injection molding, ensuring comfort and quality.

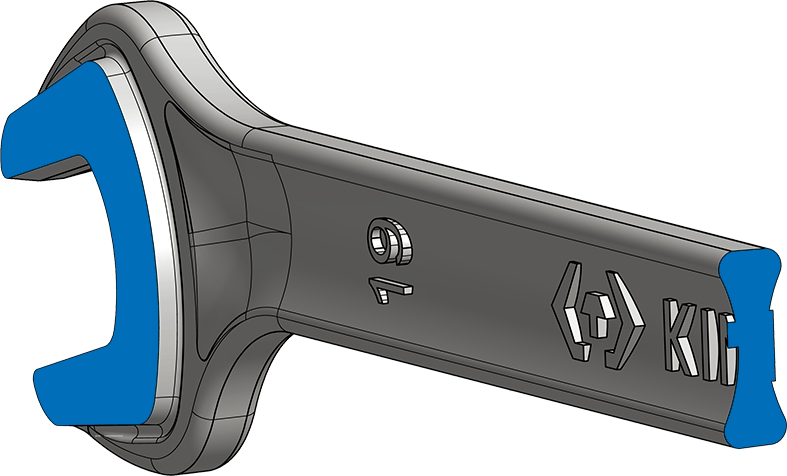

From the prototype to the mass production

Quality is essential for KING TONY®. Therefore, quality is taken into account from the beginning of the product design. The engineering team

draws 2D schematics in detail and can then obtain the 3D model of the perfect product. We create precise molds to ensure the satisfaction of the performances that were initially planned. Finally, after a prototype and multiple checks, we start the mass production for delivery to our customers.