COMPRESSED AIR SYSTEM

4 USE TIPS

1.

The maximum recommended air pressure during operation must not exceed 6,3 bars (90 psi). Higher air pressure can create dangerous operating conditions for the tool and the user.

2. Clean the hose with a stream of compressed air before connecting the hose to the air tool. This will prevent moisture and dust that can be inside of the hose from entering the tool and causing rust or malfunction.

3. Always use an air compressor with an cappropriate capacity to operate each tool.

4. The compressed air must be cooled down and a water filter must be installed at the exhaust end of the compressor. Even with a built-in water filter, water can still condense in the hose or pipes and enter the pneumatic tool mechanism, causing premature damages to the tool. Therefore, it is recommended to install an air-lubricator filter device between the pneumatic tool and the compressor.

2. Clean the hose with a stream of compressed air before connecting the hose to the air tool. This will prevent moisture and dust that can be inside of the hose from entering the tool and causing rust or malfunction.

3. Always use an air compressor with an cappropriate capacity to operate each tool.

4. The compressed air must be cooled down and a water filter must be installed at the exhaust end of the compressor. Even with a built-in water filter, water can still condense in the hose or pipes and enter the pneumatic tool mechanism, causing premature damages to the tool. Therefore, it is recommended to install an air-lubricator filter device between the pneumatic tool and the compressor.

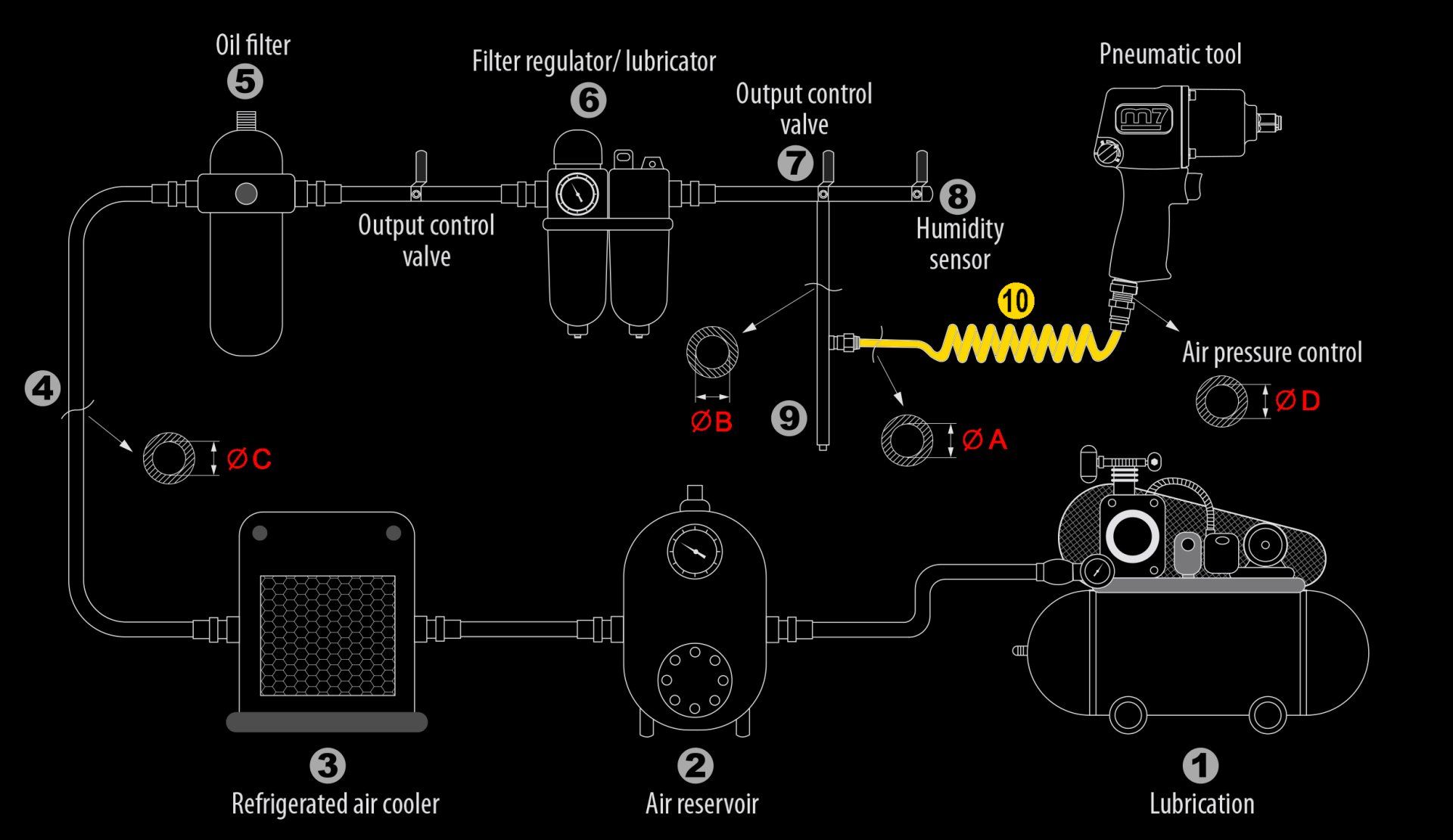

RECOMMENDED AIR REGULATION SYSTEM

PIPING DIAMETERS AND LENGTH REQUIREMENT

The diameter ∅A

required for the inlet pipe (10)

is recommended on the specification table.

The diameter ∅B required for the branch pipe (from 7 to 9 ) should be 2 times as large as ∅A. (∅B = 2 x ∅A)

The diameter ∅C required for the primary air supply (from 1 to 8 ) should be3 times as large as ∅A. (∅C = 3 x ∅A)

The length for the inlet pipe (10) should be less than 15 feet (4.5m).

The diameter ∅B required for the branch pipe (from 7 to 9 ) should be 2 times as large as ∅A. (∅B = 2 x ∅A)

The diameter ∅C required for the primary air supply (from 1 to 8 ) should be3 times as large as ∅A. (∅C = 3 x ∅A)

The length for the inlet pipe (10) should be less than 15 feet (4.5m).

M7 RECOMMENDS YOU

M7 regulator-lubricator (6)eliminate all particles up to 5 micrometers and can be filled even under pressure

SV2260

1/4" Filter Regulator Lubricator

SV2360

3/8" Filter Regulator Lubricator

SV2431

1/2" Filter Regulator Lubricator

M7 Spiral air extension(10)

is made of polyurethane, with springs at each ends to prevent the hose from cracking, and 2 male 360 ° connectors

SD series

Extention spiral bound